CNC machining has become a powerful force in modern engineering. It is changing the way we create and manufacture intricate components. CNC machines are able to attain unrivalled precision. Australia is the pioneer in this technological advancement.

CNC machineries employ the concept of subtractive manufacturing, which consists in cutting out material rather than adding it to create precise components. The CNC Machine is at the heart of this technology and is a marvellous piece of technology which has been a key element in the field of precision manufacturing.

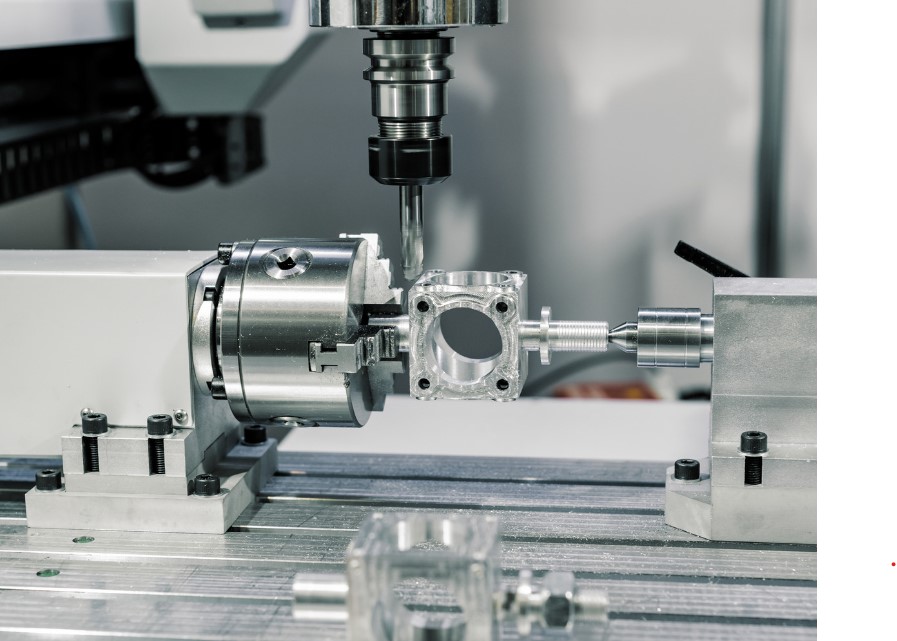

CNC machines, often referred to as digitalized computers, automate and control the movement of industrial machinery. High-speed cutters in a CNC machine are controlled by this digital code, which allows them to produce the highest precision results when transforming solid material blocks into the desired forms. The synergy between computers and CNC Machines is particularly evident in large-scale industrial facilities which are integrated seamlessly to increase productivity and efficiency.

The mechanics behind CNC machine machining is both complex and fascinating. CNC Mills begin with a solid piece of material and then employ cutting tools that are high-speed to create the desired shape. CNC is the process preferred by industries that require precision.

The CNC Machine sector in Australia is growing rapidly, driven by cutting-edge technology, a vibrant industry, and an innovative culture. CNC Machine Australia has a flourishing technological landscape including industries such as aerospace electronic, automotive, and electronics that utilize CNC machines to improve precision and efficiency.

CNC Mills can play a crucial part in shaping the manufacturing industry of tomorrow. The computerized code allows CNC Mills to produce precise parts in a variety of industries. CNC Mills, thanks to their efficiency and precision, are essential instruments for skilled engineers.

CNC machined parts offer many benefits that go beyond traditional manufacturing techniques. One of the most significant advantages is the ability to produce complex and intricate components with high precision. CNC Machines are digital, which allows for rapid prototyping, which cuts down on time and costs.

CNC Machine Tools are an additional integral element of the technological system, are a significant contributor to the efficiency of CNC machine. These tools encompass a variety of tools that assist in the machining process that range from cutting and shaping to finishing and drilling. The synergy between CNC Machines and CNC Machine Tools creates a seamless workflow, maximizing precision and minimizing waste.

CNC machineries transform industries in all fields. CNC machine is an essential tool in aerospace to create complex components that require the highest level of precision and precision. CNC machining can be used to create complex components for infrastructure and machinery in the energy sector.

CNC machineries are utilized in a variety of industries which include the automotive and electronic industries. CNC Machines are able to create intricate electronic components that are able to meet the highest standards of precision of automotive engineering. CNC machining is utilized in a variety of applications, from creating engine components to shaping intricate electronic circuits.

In conclusion, CNC machining has redefined the landscape of modern manufacturing and has CNC Machines, CNC Mills, and CNC Machine Tools standing as the pillars of the technological revolution. CNC machine machining is shaping the future for manufacturing in Australia and around the world. Its versatility as well as its efficiency, precision and speed are changing the face of manufacturing.